Expert Guide to Motorhome, Caravan and Tow Car Tyres

The only contact your vehicle has with the road is through its tyres. The total tyre contact area for an ordinary car is often little more than the size of an A4 sheet of paper. It is therefore essential you have the correct tyres fitted and they are inflated to the correct pressure. They must also be roadworthy and regularly inspected for damage and wear as it is through the tyres that you are able to accelerate, brake, corner and steer safely. Get more free help and advice when you join the Club.

The type and size of tyres fitted will have been carefully specified by the vehicle manufacturer to take account of the vehicle and its loadings. The tyres should be able to grip the road surface in most weather conditions and dissipate the heat produced as they flex when moving at speed. Needless to say, heavy demands are placed on them and they are a key safety component of your vehicle.

Structure

Modern tyres typically feature a radial type structure, although the much less common cross-ply version still exists. Both terms refer to the tyre's internal structure and the two types of tyre are quite different and they behave differently under load. It is an offence to mix radial and cross-ply on the same axle.

Cross-ply tyres are no longer widely available so when a replacement is required radials may have to be fitted. However, you can only use tubeless radial-ply tyres if the wheel is one of the safety rim type, which have a hump or flat ledge on the outer bead seat.

Older caravans, over 25 years old, may not have safety rims. In these cases it may be possible to fit radial tyres with an inner tube. Not all radial-ply tyres are suitable so consult a tyre specialist.

Camper or CP tyres

There's a tyre type often fitted to motorhomes and they're referred to a camper tyres and are marked on the sidewall with CP.

From a tread pattern and load bearing ability they're the same as the commercial van counterparts but they will have modifications in construction to enable them to withstand the much lower activity levels expected. They may have enhanced aging inhibitors and a thicker butyl inner liner so they cope better standing still for longer periods.

It is not compulsory to use these with a leisure vehicle but it is recommended as many motorhomes are laid up for months at a time, something a normal van tyre was not designed for.

Tyres for Electric Vehicles or EVs

Larger more powerful EVs can be good towcars but it is worth noting that being so much heavier combined with more instant torque than their diesel or petrol counterpart that they're often supplied with a different specification of tyre.

The rubber tread compound will be different and the sidewalls fortified, they will also have lower rolling resistance for maximising range. You can fit non-EV tyres to an electric car, however industry testing has shown this can effect range by up to 20%.

Tread

Most tyres supplied in the UK are a summer tyre, which are optimised for use in warm months and will perform well enough in most conditions. For those wishing to travel further afield or live in cooler parts of the UK there are also all-season and winter tyres to choose from.

An all-season tyre tries to achieve everything - offering reasonable performance in cold, snowy, warm or wet conditions - a tall order for any tyre. They have a place in the market but applications can be quite limited, however over the last few years tyre tread and material technology has come on considerably making such tyres a serious consideration for those living in more marginal parts of the country.

To cope with snow covered roads, the pattern is optimised to grip on the soft surface by providing open gripping edges and also to trap small amounts of the snow within the pattern. This snow then adheres to the snow on the road surface – snow grips to snow. Think of rolling a snowball over a snow covered lawn, the ball gets bigger and bigger.

The tread rubber properties are modified so that they are less sensitive to temperature change. Standard summer tyres become harder as the ambient temperature plummets, whereas a winter tyre tread rubber remains compliant at temperatures below 7C and hence keys into the road surface generating better grip.

Tyres marked M+S (but not carrying the snowflake motif) are not classed as full winter tyres. The M+S stands for mud and snow or slush, which indicates they have a traction type tread pattern and although they may give benefits when fitted on the driven axle of a car, they will offer little benefit if fitted to caravans. Note: All winter tyres that carry the snowflake motif are also marked M+S, but not all tyres marked M+S are marked with the snowflake.

In many Alpine and Scandinavian countries, tyres with at least a M+S rating are compulsory through the winter months even for temporary foreign visitors. This is also becoming an increasing trend across central Europe and there may be local laws dictating a minimum tread depth for winter tyres. The latter varies between countries but it is worth noting that a winter tyre cannot perform properly on snow once the tread is below about 4mm, so check with the local tourist board what the limits are and also whether snow chains are compulsory equipment. In simple terms the rule is that tyres must be suitable for the road and weather conditions.

This winter tyre is worn out but still legal to use in the UK

This winter tyre is worn out but still legal to use in the UK

When you wear out a pair of tyres on a car or campervan, particularly where the powertrain is front wheel drive, consider having the new tyres fitted to the back axle and bring the older slightly worn rears to the front. This will then have your newest and better pair of tyres on the rear axle where they can control the vehicle better. This advice is now given by many tyre manufacturers and driving organisations and it is considered good practice to fit your best tyres to the back axle. Always consult the vehicle handbook though, as some manufacturer recommendations may differ from that described above, for example some all-wheel drive vehicles need the tyres to be rotated periodically to keep the wear even.

What is described as a winter tyre is one that provides higher levels of grip on ice and also on cold, wet or damp road surfaces. As a result they provide higher levels of grip on snow. Winter tyres are marked on their sidewall with a snowflake motif inside the outline of a mountain peak (pictured above). They achieve their performance by a combination of a dedicated tread pattern and specialised tread rubber type.

The tread pattern is a key part of a tyre and can be optimised in many different ways, for example to disperse water, assist in reducing rolling resistance for fuel economy or to grip on slippery or loose surfaces.

Load and speed

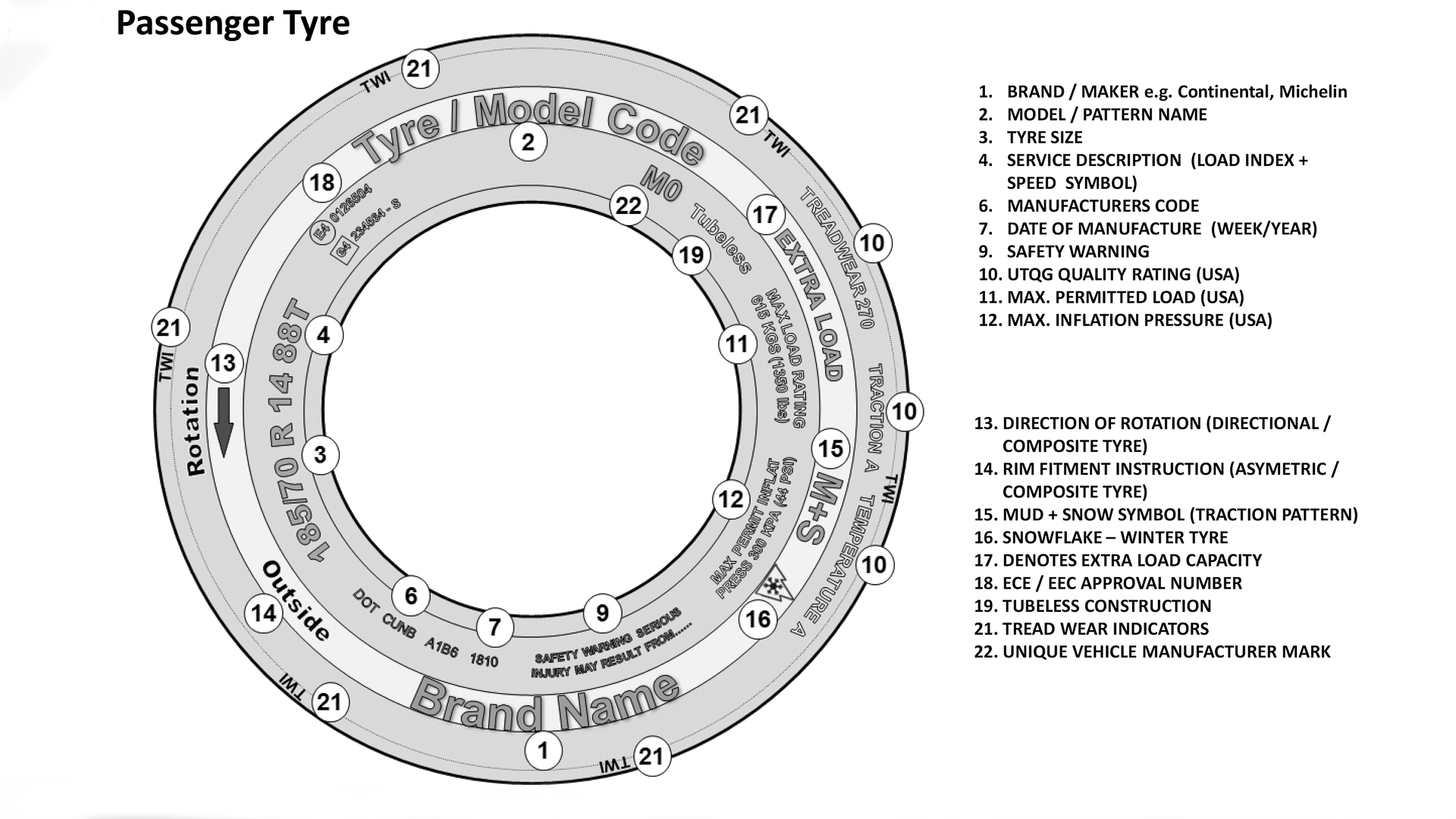

All tyres are marked with a series of codes to tell you the maximum load they can carry and their maximum speed rating.

Many vehicles are equipped with tyres with a speed rating considerably higher than the legal limits - if a speed rating is lower than the legal limit then the tyre's limit takes precedent. Note: A tyre's speed symbol is also an indicator of its performance under cornering, acceleration and braking.

Vehicle tyres are often supplied with a load carrying capacity in excess of the maximum permitted for the chassis. Rather like having a high speed rating, this is a useful surplus capacity to have. When you are looking for replacement tyres seek advice from the suppliers, and avoid going to a lower speed or load index unless you are sure the tyres can still cope with your demands. Taking a tyre beyond its weight limit is overloading which renders the vehicle illegal and potentially unsafe.

Caravans may have a light commercial van tyre or a dedicated trailer tyre, both are suitable for this as what matters is the ability to bear the load.

Load and speed (continued)

Load and speed (continued)

The highest speed allowed for towing in this country is 60mph but can be higher in some other countries. The weight of a motorhome dictates the speed limits that should be adhered to.

Older caravans may have been originally supplied with tyres that on paper were under-rated, which is due to something known as the bonus load, where a tyre's load capacity may be increased by 10 per cent when the speed was restricted to 62mph.

If the bonus load is taken into consideration then a tyre with a load index of 80 (450kg per tyre) can carry 900kg plus ten per cent bonus load making a maximum total of 990kg - subject to a strict maximum speed of 62mph. For safety reasons the caravan industry has moved away from this practise and it's quite common to find a modern tourer running higher load capacity tyres where the maximum technically permitted laden mass (MTPLM) of the caravan does not exceed 90 per cent of the combined tyres - load capacity.

Tyre pressures

It is the air pressure inside the tyre that supports the load and therefore inflation pressures are dictated by the load upon the tyre. You will find the recommended tyre pressure for your motorhome, caravan or trailer in the owner's manual. You should always adhere to the pressures given in your handbook.

Always check pressures when the tyre is cold as the pressure will rise rapidly after only a few miles due to the heat generated. Under-inflated tyres are a major concern, as they can overheat in operation and in the worst case scenario fail. Over inflation can cause a poor or unstable ride and uneven wear characteristics. Over inflated tyres are also more prone to impact damage as they are less able to absorb road shocks.

Generally, tyre pressures for caravans and trailers are higher than when the same tyre is used on a car, which reflects the higher load placed upon them. Motorhomes may have different axle loads from front to back and therefore the tyre pressure will need to be adjusted to suit, the chassis handbook should offer guidelines. Trailer wheels are normally smaller than those found on caravans and cars and often require higher pressures to enable them to support the weight on the axle.

If the required tyre pressure exceeds 60psi then a higher specification valve will be needed (most commonly one with a metal stem and high pressure valve cap). It is important to tell the supplier of a new tyre the operating pressure so the correct valve is fitted.

Car manufacturers often advise raising tyre pressures when carrying a full load, particularly on the rear axle. Large SUV-type vehicles may not need a significant tyre pressure change when towing but more conventional cars may well need an increase as the load on the hitch can be quite significant. This information should be on the car somewhere (see below).

If you are unsure what pressures your car tyres should be, contact the tyre or vehicle manufacturer. In the absence of any specific tyre pressure recommendations for towing, inflate the rear axle tyres to between four to seven psi above the maximum specified in the vehicle handbook, however do not exceed the tyre's maximum inflation limit, identified on the sidewall of the tyre.

If you intend towing at the higher speed limits permitted abroad then you may need to adjust the tyre pressures on your unit and reduce the tyre loading (see Load and speed section, page 2). If in doubt, check with your trailer manufacturer or tyre specialist.

Tyre care

You really can't check your tyres too often. Always check them before each long journey and give the tyres a visual inspection and check their pressures at least once a month.

When doing so, look for cracks, cuts, bulges on or distortion of the tread and both sidewalls, and be sure to remove any stones and other debris trapped in the tread. Wipe off any oil, grease or fuel. If you discover uneven wear, this often suggests a fault in the vehicle's suspension geometry, so seek professional advice as to the causes.

If you have a puncture then repairs should be entrusted to a specialist. Holes should be plugged and patched to comply with the latest edition of British Standard BS AU 159, and inner tubes should never be used as a repair method.

A screw has punctured a tyre and its subsequent repair

A screw has punctured a tyre and its subsequent repair

It is rare to wear out the tread on caravan or trailer tyres as they generally do not do the same mileage and are not subject to the same acceleration and steering loads of a car's tyres.

Tyres have aging inhibitors within their compound, but for these to work correctly heat from frequent use is required, so paradoxically the lack of activity often experienced by a touring unit’s tyres ages them faster. This is made worse by ground level pollution, ultra violet light and salt spray. Thus a caravan stored at a sunny seaside location will have rapidly aging tyres.

Cracking or crazing on the side indicates that the tyre could have aged, in which case it should be replaced as soon as possible. UV-related aging may well be accelerated when camping regularly in sunny climates.

This tyre's showing signs of aging

This tyre's showing signs of aging

If you can remove the wheels from a caravan for a period of time, store them in a dark place or cover them with hessian or some other breathable fabric (don’t use a plastic bag). However, before removing them, check that you do not infringe the terms of any insurance cover as some policies require a wheel clamp when the caravan is in storage. You cannot fit a wheel clamp without a wheel! Ensure the valve cap is in place. Besides acting as a dust cap some incorporate a rubber seal that acts as a last line of defence against air loss if the valve seal fails.

The Camping and Caravanning Club recommends a tyre is replaced at a maximum of seven years from the date of manufacture, thus any caravan or motorhome tyre that now has a date code of three digits should no longer be in service (see Tyre age identification, right). Some insurance providers for caravans will not cover tyre-related claims when the tyre is over five years of age unless you have proof they have been annually inspected by a competent person. Replacement tyres should be available from good tyre supply companies but it is likely they will need to be ordered in.

Due to the lengthy supply chain for tyres and subsequent delays in manufacture of a caravan or camper, the tyre may be quite old by the time the unit is registered.

Detailed tyre inspection at an annual service

Detailed tyre inspection at an annual service

Tyre sealants

There are two types of tyre sealants in the marketplace - pre-puncture and post-puncture.

The post-puncture type may be supplied with a vehicle as an alternative to a spare wheel and can be bought as an aftermarket accessory in the form of a fluid and pump or as a one-shot aerosol can. These are designed as an emergency fix, with a sealing fluid delivered through the valve that will close up most normal punctures within the tread area. Follow the instructions supplied closely.

Sealant pump and replacement bottle of tyre sealant

Sealant pump and replacement bottle of tyre sealant

Pre-puncture sealants are a thixotropic fluid with other materials in suspension that is delivered through the valve tube with the core removed. This fluid coats the inside of the tyre and when a penetrating object is removed from a tyre the air pressure forces the sealant into the void closing it. These sealants can be very effective but you won't know what other damage has been done to the tyre's casing and these sealants could mask a more severe problem. For this reason the tyre industry does not generally recommend their use.

Neither pre- nor post-puncture sealants can be considered as a permanent repair to a punctured tyre - they are simply a means to allow limited travel to a place of safety where a permanent repair can be carried out or a replacement tyre fitted. A number of tyre makers have products that are pre-loaded with a sealant. They are available in a number of sizes, check with your supplier whether any pre-sealed tyres are available for your car.

Tyre age identification

Since the year 2000 tyre age has been easy to read as it is given in a 4-figure digit - the first two numbers are the week of manufacture and the second are the year. The example here shows a tyre made in week 08 of 2007.

Older tyres are dated slightly differently and feature a three digit code where the first two digits denote the production week and the third denotes the year. An additional triangular indentation after the year clarifies that it is a tyre made in the 1990s, no triangle mark is a tyre from the 1980s or earlier.

Staying legal

It is illegal to have a tread depth of less than 1.6mm around the entire circumference of the tyre for trailers and vehicles under 3,500kg gross weight. Vehicles over 3,500kg gross weight must have 1mm of tread depth over the same area. You can measure the depth with an inexpensive tyre depth gauge obtainable from most tyre and accessory outlets.

Ideally tyres should be changed prior to the legal limit as wet, corner and braking performance diminishes considerably once the tread depth falls below three millimetres.

In the UK the Road Vehicles (Construction and Use) Regulations specify the conditions a tyre must satisfy in order that it can be legally used on the road - this means the load index, speed rating and tyre type need to be suitable for the vehicle or trailer they are fitted to.

Safety bands

Modern wheels have safety features designed to retain the tyre in its inflated position on the rim, but never the less a significant pressure loss can dislodge the tyre resulting in possible loss of control.

When the tyre deflates it begins to move across the wheel. With nothing to grip it, the edges slip into the middle of the wheel - known as the well. The wheel loses its traction and you may lose control.

The fitting of a well filler, like a Tyron Multiband (see below), may prevent the tyre coming off your trailer or caravan and help you to come safely to a halt. The band fits in the well of the wheel so when the tyre deflates the band prevents the tyre from falling into the well. The tyre remains on the rim allowing the deflated tyre to form a cushion between the wheel and the road surface. The effectiveness of these bands is well established and many insurance companies offer discounts on premiums if you have a set fitted. Tyron bands require specialist tools to remove - see below.

Portable Tyron Multiband tool

The device shown is a portable Tyron fitting tool. It is light and compact enough to be carried with the wheel changing tool kit. It has been made in response to the comments that in some countries safety bands are unheard of and tyre shops do not have the appropriate equipment to fold the tyre back to refit the bands.

Retreads

In normal use the tread of a car tyre will wear while the tyre casing or structure generally remains in good condition. A retread is a tyre that has had a new tread applied to the casing.

There is no reason why you should not use a retreaded tyre on a caravan or trailer - in the past they were to be made to the British Standard BS AU 144. It is a legal requirement that retreads must be marked with the words Remould or Retread, the British Standard number and the maximum speed permitted denoted by the speed symbol.

Since 2004 retreads have been subject to European regulations ECE 108 for car tyres and ECE 109 for commercial vehicles, and will be -E- marked to show compliance.

Many retreads are made to specifications that may exceed British Standards - but not all. Be aware that there are unscrupulous dealers about. That said, good retreads can be cheaper than new tyres and should perform equally as well.

Revised tyre labelling

Tyre labels showing basic efficiency information has been around since 2012.

The label was revised during 2021 and has been brought in line with the labels you will find on domestic appliances.

Using a simplified A-E, where A is best, for both rolling resistance (economy) and wet grip will be shown in this way, the noise rating remains shown in decibels but now rated A-C.

Also, where appropriate a snowflake in a mountain motive for winter/snow tyres or a mountain inside a triangle for a 'Nordic' or ice tyre.

It is expected the old label will remain on existing stock and will phase out in due course. The new label is expected to be used in a digital format on both websites and at the point of sale enabling the consumer to make a more informed choice based on their personal needs.

Tyre pressure monitoring systems

A valve mounted TPMS sensor fitted and a close-up

A valve mounted TPMS sensor fitted and a close-up

Tyre pressure monitoring systems (TPMS) will become compulsory on all new cars sold from November 2014 onwards. At this time there's no plan to introduce such technology for trailers so any kits are to be found in the aftermarket.

These systems are very useful as they inform the driver of the tyre pressure, and with some systems tyre temperature, in almost real time.

Look for a system that is complaint with ISO 21750, the display device must be able to be mounted where it can viewed from the driver's seat, both audible and visible warnings to be given when a tyre has gone outside the pre-determined parameters and there should be a warning given where a fault is detected or where there is a low battery.

The sensors themselves should be direct reading and there are two types. Internal sensors can only be realistically fitted by a tyre fitter, and it is also important to consider their battery endurance.

External sensors replace the valve cap and can be installed and the battery easily serviced by the user.

Compact and space-saver spare wheels will be discussed in our forthcoming wheels guide.

We have a number of how to videos on our Youtube channel. One for tyre care and another about tyre inflation.

Contacts

Web: TyreSafe

Tel:01787 226995

Web:Tyron (Safety Multibands and TPMS)

Tel:01509377677