A Guide to Tent Material

Choosing a tent can be a challenging business. There are a wide range of materials involved, from the fabric on the outside of your tent to the pegs you use to hold it down. This guide looks at some of the materials you are likely to encounter when buying a tent. You can find out more buying advice here: Choosing a tent layout.

Much of the advice here is also relevant to other forms of camping, see our Expert Guides on Buying an Awning and Trailer Tents for further reading

Tent fabrics

Most tents will have two layers – an outer cover known as the flysheet and an inner tent for sleeping. In almost all cases, you won’t have a choice of fabric for the inner tent, so as long as it is breathable (to prevent condensation building up overnight) you should be fine. However, there is a range of materials available for the flysheet. Read on for more details.

Polyester

Most tents on the market today are made of polyester. This man-made fabric comes in many weights and with a variety of coatings, many of which are given brand names by their respective manufacturers.

A typical polyester tent

A typical polyester tent

Polyester has similar properties to nylon (see below), but it does not stretch or shrink as much and by using specialist coatings can be made to be quite UV stable. Higher grade polyester tents may also have a ripstop weave, this is identified by a cross hatching in the weave and inhibit tearing.

As a result, most tents on the market today – especially family ones – are made from polyester.

Nylon

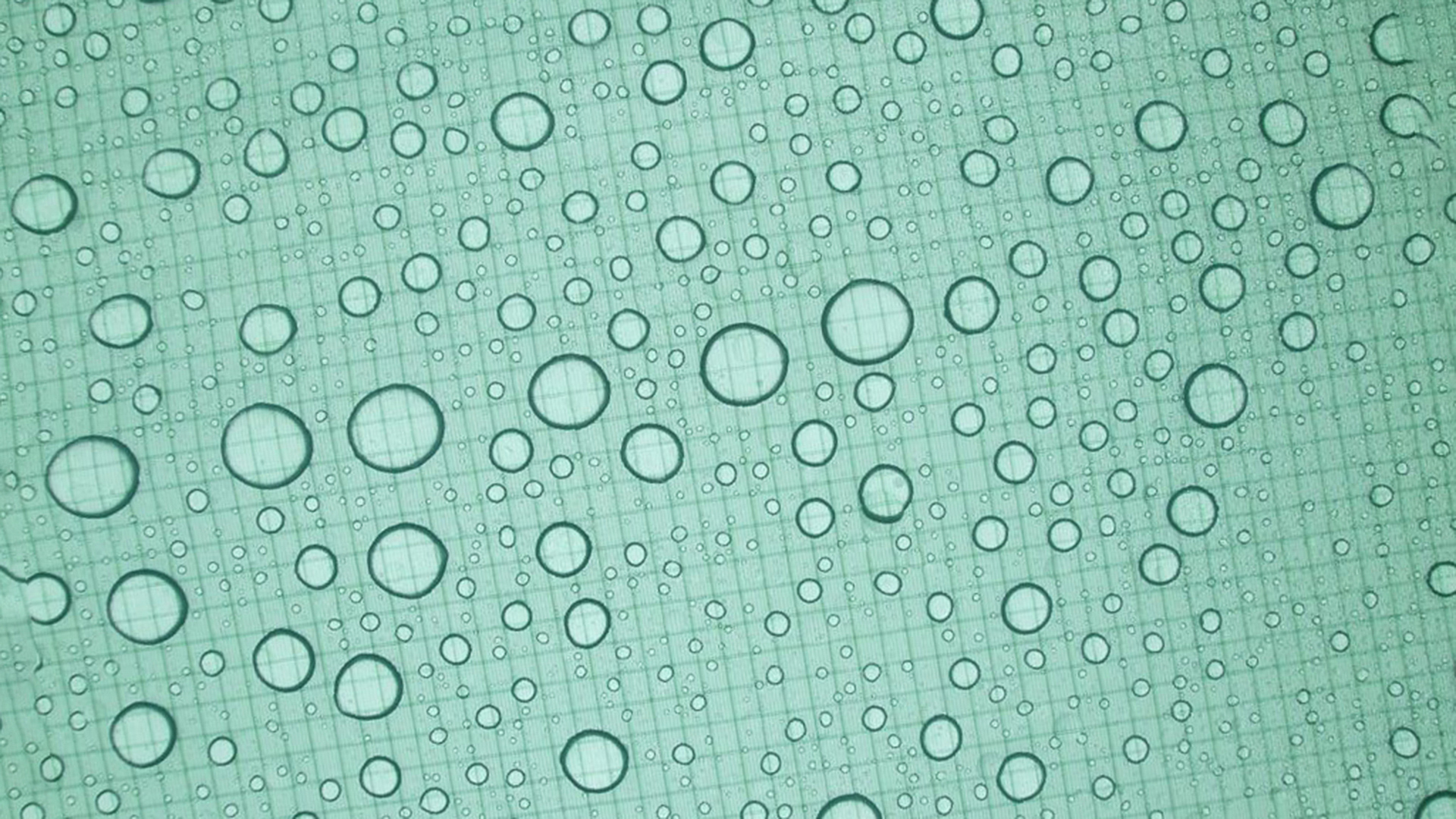

Water beading on ripstop nylon

Water beading on ripstop nylon

Lightweight tents are often made of nylon. This man-made textile is normally coated to make it more durable to both abrasion and UV, with coatings such as acrylic, polyurethane (PU) or silicone.

One disadvantage of nylon is its tendency to ‘ladder’, which is when a small hole propagates across the fabric rapidly. Top-of-the-range nylon fabrics include a ‘ripstop’ mesh of thicker nylon strands that prevent a small tear propogating. However, some cheaper nylon fabrics have a ripstop crosshatch pattern embossed – simply to look the part – so it's worth checking whether the tent you are looking at is really ripstop fabric.

Composites

The latest generation of expedition tents are using laminated polymer or composite textiles. For example ULTRA from Terra Nova uses an ultra high molecular weight polyethylene (UHMWPE) mat coated on both sides with a thin polymer film. The result is a very robust and lightweight material, the textile can also be bonded allowing for a greater tensile strength than a sewn join.

Polycotton or coated-cotton

A polycotton tipi style tent

A polycotton tipi style tent

An alternative to traditional 100% cotton canvas is polycotton, or lighter-weight cotton with a weather-resistant coating. These materials have many of the qualities of 100% cotton canvas but tend to be lighter in weight and lower cost. Many family tent manufacturers have polycotton or coated-cotton units in their ranges, such as Outwell and Vango.

Cotton

A modern cotton tent

A modern cotton tent

Before the 1960s, tents were generally made of natural fabrics such as cotton canvas. The Camping and Caravanning Club’s founder Thomas Hiram Holding even used silk for his lightest tents.

Today cotton tents are available from specialist manufacturers like Cabanon, Karsten and Bell Tents. Cotton canvas is a wonderful fabric for tents because it remains cool in summer, keeps the warmth inside in winter and rarely suffers from condensation. One result of this is that you do not generally need an inner tent in a cotton canvas unit.

Canvas is also a better sound insulator, so cotton tents often seem quieter inside than nylon or polyester ones. A cotton canvas tent will normally outlast one of man-made fabric, sometimes by several decades, but it will weigh significantly more and probably cost a fair bit too.

Cotton tents can also require more maintenance than ones of man-made fabric. For example, a new cotton tent will need to be weathered to prevent it leaking. This involves soaking it a couple of times, allowing the threads in the canvas to swell slightly and close any tiny gaps where water can seep through.

Groundsheets

Groundsheets in most tents today are of sturdy PVC. You will probably want a fully-waterproof groundsheet in your sleeping area, but if you have a choice, it is worth considering a breathable one elsewhere because it will keep the grass beneath your tent in better condition for future campers.

A typical footprint used to protect the underside of your tent

A typical footprint used to protect the underside of your tent

If the ground is already particularly muddy, you may want to have a footprint – which could be purpose designed or simply a piece of polythene from a DIY store or builders’ merchant – to go under your groundsheet to keep the mud at bay.

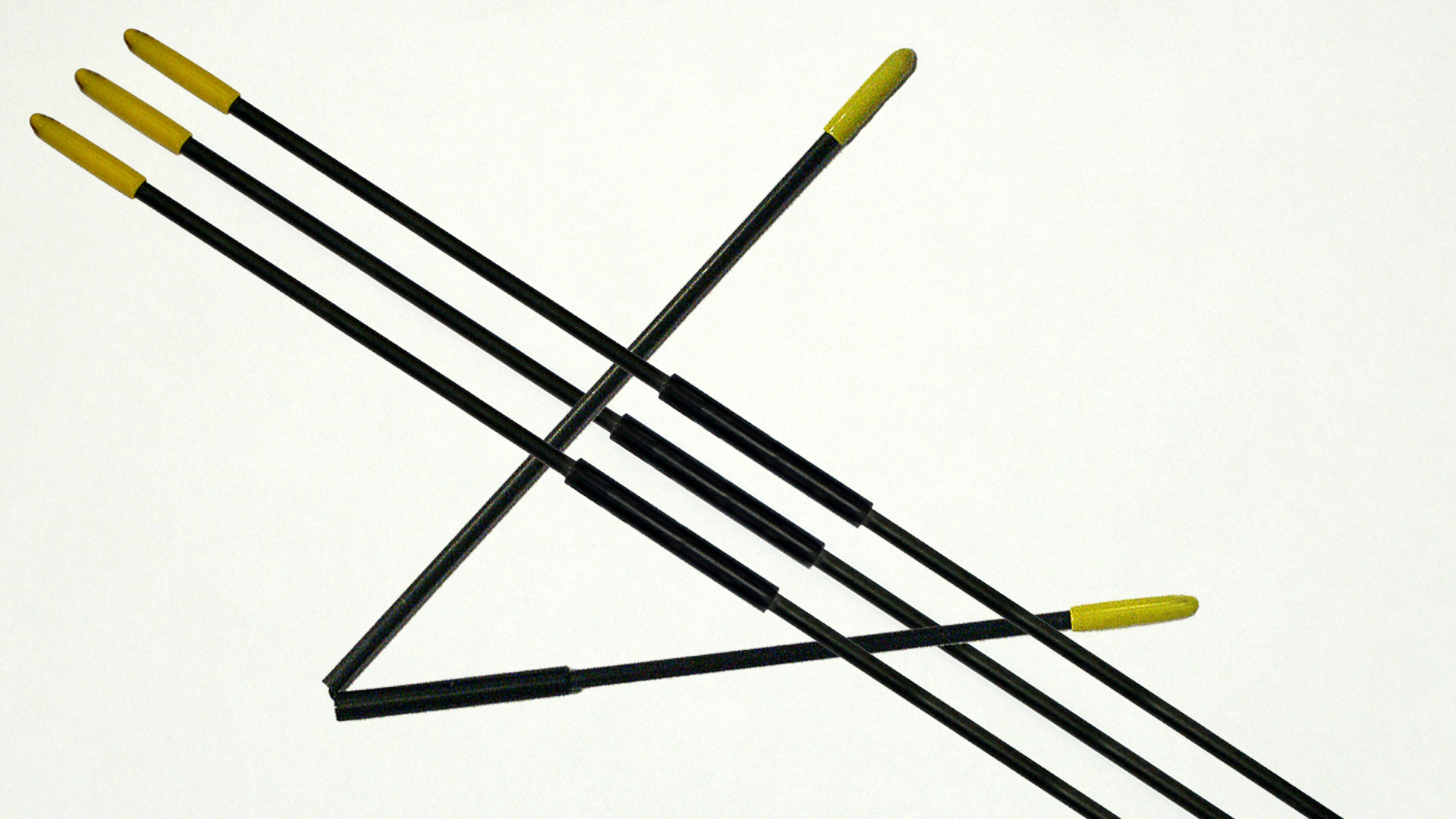

Poles

Glass-reinforced plastic (GRP) – also known as fibreglass –is a popular material for tent poles because it is relatively cheap to produce, lightweight and bends easily around the curves of a tent. It is often found in small- and medium-sized dome and tunnel units or as extra poles (over a porch or similar) in larger ones.

GRP is made from thin glass strands held in a resin. Some such poles are surrounded by an outer wrapping and appear under a brand name, such as Durawrap or Dynaflex. One disadvantage of the material is that when a pole breaks or fractures – and they can do, especially if they are accidentally mis-threaded in a sleeve – the break can have sharp glass splinters.

Steel

Steel tent poles are generally painted, plated or coated to prevent them rusting, and need to remain that way. Steel is a strong, heavy material, so you will normally find these poles in larger tents, and they are not designed to bend around the curves of a tent.

A coated steel pole

A coated steel pole

If your chosen tent has steel poles with angled corners, check the thickness of the material at these corners because they can be weak points. An accidentally-bent steel pole can often be straightened, but it will never have all the strength of its condition before the incident.

Aluminium alloy

Aluminium is a much lighter metal than steel and it can bend around curves like GRP. For extra strength aluminium is combined with another metal to form an alloy.

These materials are more costly than GRP but the strength and weight saving (over steel) mean they are often sold with lightweight, backpacking tents.

Aluminium poles are lighter than steel but cost more

And also…

At the top end of the market, you will find poles in hi-tech materials. Carbon fibre ones, for example, are incredibly light, strong and perfect for the curving structures of many tents.

Carbon fibre poles are light and strong

Carbon fibre poles are light and strong

And finally…

One advantage of buying a slightly more-pricey tent from a well-known supplier is that you are likely to be able to buy a replacement part if you accidentally break or tear something.

Replacement poles, pole sections and end caps (known as ferrules) are normally available from your local camping equipment retailer, or a specialist spares stockist such as www.tentspares.co.uk.

If replacements are no longer available for your particular tent model, you can normally buy a standard piece of pole with the correct diameter and cut it to length.

Pegs

When you buy a tent it is likely to be supplied with standard, straight steel pegs with a circular cross-section, sometimes called pins. If conditions are good, these may be sufficient, but in many cases it is worth investing in some additional pegs to keep your tent securely on the ground. Pins can be easy to put in the ground, but they often bend if they hit something hard in the ground and they are also easily dislodged.

Some campers with many years’ experience will carry a selection of pegs, each suited to different ground conditions. It is always worth having a few spares – even of the most basic pins – to replace any broken or lost ones.

There are many different types of peg to suit the ground conditions

Pressed steel or alloy

Pegs with a shank with a flat cross-section generally give better grip than standard steel pegs.

Lightweight pegs

If you are carrying your kit yourself, you may consider alloy pegs or titanium ones to reduce weight. These need to be used carefully as they are more likely to bend under the mallet. You also need to be sure they will be good enough to stay in the ground keeping your tent down in the wind.

Moulded plastic

There are many shapes and sizes of moulded plastic pegs on the market. Many are remarkably strong, even though they are light in weight. Some larger tents are sold with moulded plastic pegs for the main guylines and steel pins for the remaining guys.

Rock pegs

Rock pegs are designed for especially hard ground – perhaps stony or frozen. They are normally made from steel and generally have a head to take the guyline, perhaps made of plastic.

Screw-in pegs

These pegs have a strong grip and are designed to stay in the ground unless you unscrew them. Many people use a cordless drill to put them in place and extract them.

Groundsheet pegs

Groundsheet pegs normally have flattened tops so you can stand on them without spiking your feet.

And the rest

You will find a wide range of pegs on sale at your local camping retailer or online, with extra features such as glow-in-the-dark heads or extended tops to anchor them to the ground. After a few camping trips, you will soon decide whether you would like to splash out on a different type. Many enthusiasts on camping forums are happy to discuss the options.

Putting in and removing pegs

Unfortunately there are too many campsite accidents when a peg breaks through the sole of a shoe or boot. So it is worth investing in a decent rubber-headed mallet to help drive your pegs into the ground (unless you are only using screw-in ones). You may also like to buy a peg extractor for the end of the holiday – it is a good way to save your hands and prevent pegs being left in the ground.

Guy lines

Modern guy lines (or just 'guys') will be of synthetic cord so they shouldn't shrink or slacken as they get wet or dry. They will fix to the main outer tent or flysheet via a metal or plastic ring. There should be an adjuster to allow you to set and keep them at the right tension.

Guys should normally follow the lines of the seams of the tent, to give stability, and shouldn’t cross each other. Position the adjusting sliders so there’s room to make the guys longer or shorter during your stay and don’t forget to check them regularly to make sure they’re not loosening or getting too tight.

Braided synthetic guy lines can fray. You can heat seal the ends by touching them in a flame and rolling between a damp thumb and finger but watch out, molten nylon can stick and burn. Replacement guy lines can be found in most camping accessory shops.

A tent on fire

No tent fabric is fireproof. Many fabrics will be fire retardant but all tents will burn and most will burn remarkably quickly.That’s one of the reasons you should never use any equipment with open flames in a tent and, however romantic you think it may be, never use candles in or near a tent.

If your tent does catch fire there is only one thing to do. Get everybody out and get clear of the tent as quickly as possible. Save yourself and worry about the tent later.

Most tents will have a fire safety label

Most tents will have a fire safety label

Traditional tent campers adopt an excellent habit – they all keep a fire-bucket full of water or sand outside their tent. Nothing is more effective if a tent does catch fire than half a dozen good neighbours each throwing their own bucket of water on the blaze.

The Club has a rule that units should always be 6m apart from each other. The law states that all units should be pitched at a distance to prevent the spread of fire and the outdoor industry has agreed to a minimum of 3m between tents.